I share a lot of content online—videos, photos, behind-the-scenes factory footage. People react in different ways. Some appreciate seeing how things really work. But I know others have questions they’re not sure how to ask. I can see it in their comments and messages. The question basically comes down to this: “You keep telling us you’re one of the top curtain accessory factories with your own manufacturing operation, handling huge volume orders. So why do we keep seeing workers in your videos doing such simple manual tasks? Shouldn’t everything be automated when you’re dealing with that kind of scale?”

That’s a fair question. Let me explain how this actually works.

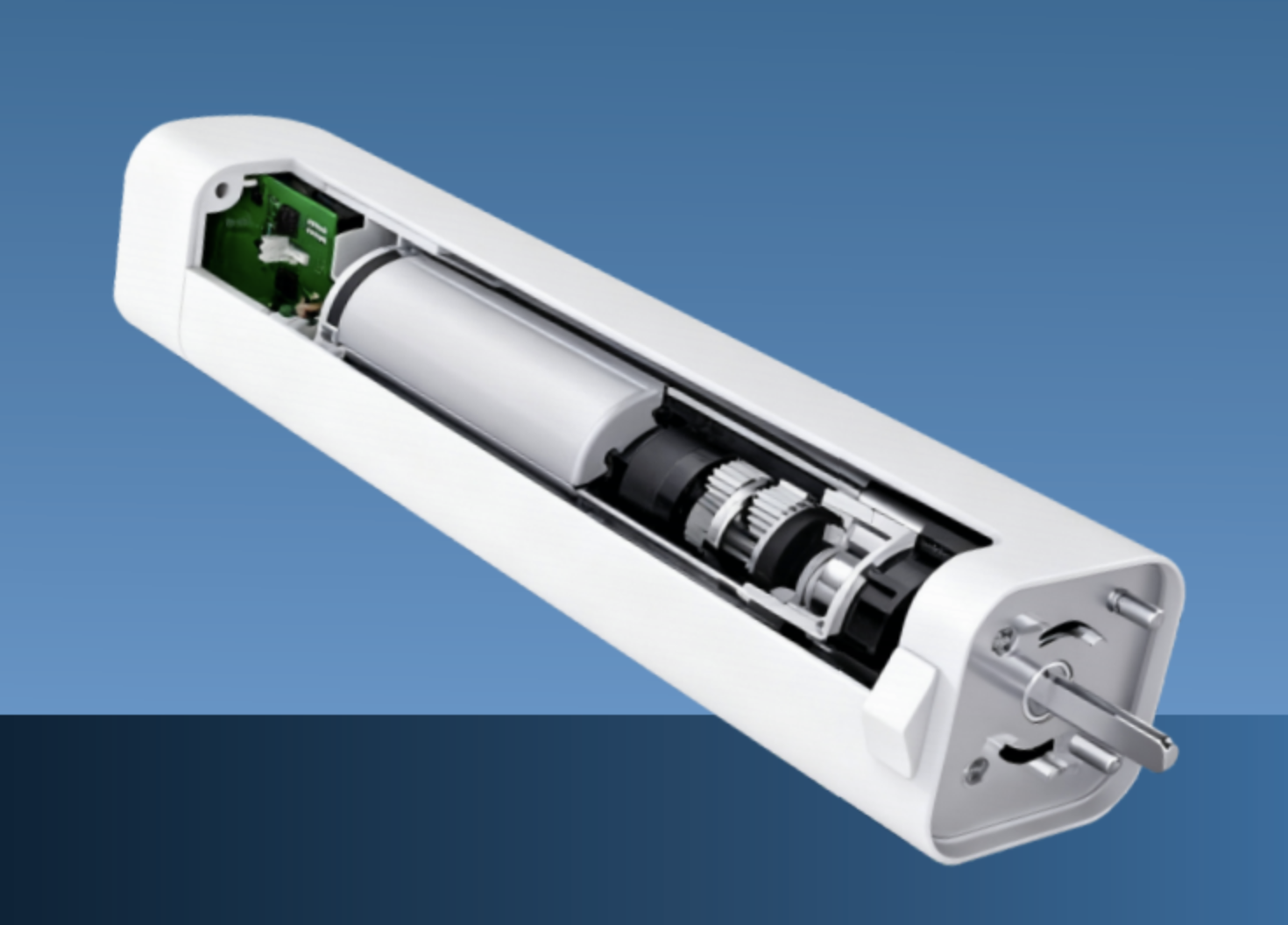

Let me show you what a finished strung runner actually is. This is the complete piece that goes straight onto a curtain track. That hole at the bottom? That’s where your customer attaches the curtain hook. That’s what makes the whole system work. If you’ve never worked in manufacturing, you probably think this is straightforward—just mold it, put it together, ship it out. But it’s not that simple.

A runner doesn’t come out of one machine as a finished piece. We have to build it in stages. Each stage matters. Some stages work best on machines. Some stages need skilled people to do them right. It took us years to figure out the optimal balance between machines and manual work that keeps quality high while moving volume efficiently.

Here’s what happens in the first assembly stage: we use a machine to attach the two black wheels to the main body using fasteners. This is the kind of work that’s repetitive and identical every time, so machines are perfect for it. But this wasn’t always the case. More than ten years ago, workers did this step by hand. As we grew and volume increased, we invested in machinery to handle this repetitive work. That’s the natural evolution for factories that want to improve efficiency.

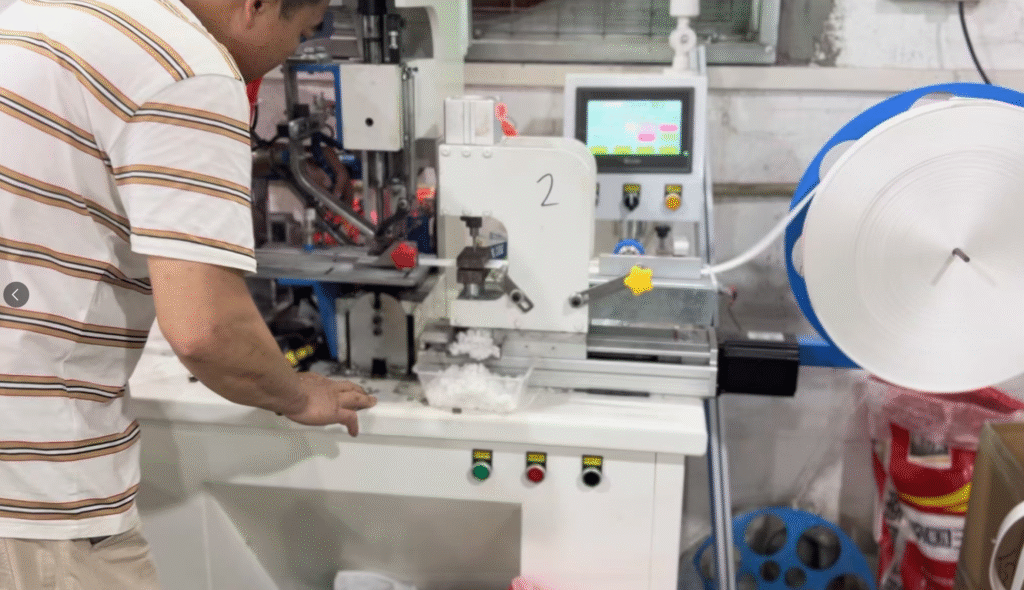

Then comes the final critical step: inserting the ball bead into the runner channel. This is what allows the runner to glide smoothly on the track and hold the curtain securely. This is also the step where you see workers with hammers in our factory videos.

Here’s why this step is different: we don’t manufacture just one type of runner. We make many different types. The wheels come in different sizes. Different materials. Different connector designs on top. Depending on which runner specification we’re producing, the bead insertion angle and method changes. When you add it all up, we’re producing more than a dozen different runner specifications.

This is why we can’t simply build one machine and automate everything. You would need to engineer and build a completely separate machine for each different runner type. That means thousands of dollars investment for equipment that might only run a few times per year on smaller orders. That’s not economical. That doesn’t make sense from a business perspective.

So here’s our approach: we’ve engineered machines that handle all the universal features—the parts that are identical across every runner type. The basic body structure, the wheel attachment point, the general form. Machines excel at this repetitive, consistent work. We invest heavily in machinery for these stages.

But the variable parts—the bead insertion with different angles, the directional vs. multi-directional connectors—we keep these as skilled manual work. Some runner types need to be inserted at a precise angle. Some are multi-directional and much harder to tap in correctly. Right now, no machine exists that can handle this level of flexibility and precision simultaneously. We could potentially develop one, but it would only work for one specific runner type. The investment wouldn’t justify the return.

So when you see that image of workers tapping beads into runners, that’s not a limitation we’re working around. That’s a deliberate choice we’ve made because it’s the right way to handle the work efficiently while maintaining quality.

And I want to be clear about something important: these aren’t entry-level positions filling because workers have no other options. The most experienced workers doing this bead insertion work earn salaries that are competitive with white-collar office professionals in first-tier Chinese cities. Some of these people have been working with us since we started the factory. We’re not compromising on worker compensation to cut costs. We understand that good products require respecting the people who make them.

That’s the real answer to the question.