When it comes to outfitting commercial spaces—whether hotels, office buildings, or residential complexes—choosing the right curtain track system is crucial. The curtain runners you select will impact not only the aesthetic appeal of your project but also its durability, functionality, and long-term maintenance costs. This comprehensive guide will help you understand what to look for when buying heavy-duty aluminum curtain runners from manufacturers, ensuring you make informed decisions that benefit your project and bottom line.

What Are Curtain Runners and Why Do They Matter?

Curtain runners are the mechanical components that allow curtains to glide smoothly along aluminum tracks. They consist of wheels or rollers housed in a carriage that moves along the track profile. For commercial applications, these aren’t simple components—they’re precision-engineered parts that can make or break your window treatment system.

Heavy-duty curtain runners designed for commercial use must withstand frequent opening and closing cycles, varying weather conditions, significant weight loads, and years of continuous use without degradation. Understanding the mechanics and specifications of curtain runners helps you choose products that deliver value, reliability, and performance.

Understanding Critical Specifications for Commercial Applications

Track Profile Dimensions: Getting the Perfect Match

The most critical specification is the track profile size. Standard commercial aluminum curtain tracks typically come in these dimensions:

- Width: 28mm (most common for commercial applications)

- Height: 23mm standard profile depth

- Base Width: 30mm

- Wall Thickness: 2.0-2.6mm

These measurements ensure compatibility between runners, tracks, and mounting hardware. Before placing a wholesale order, always verify that your curtain runners match your track specifications exactly. A 28mm wide runner won’t function properly on a 25mm track, and undersized runners will derail frequently, causing operational headaches and liability concerns.

Runner Wheel Performance Features

The wheels or rollers inside your curtain runners directly impact smoothness and longevity:

- Wheel Material: High-quality plastic or nylon wheels provide smooth, quiet operation

- Wheel Design: Dual-wheel systems distribute weight more effectively than single wheels

- Bearing Type: Precision ball bearings enable smoother gliding with less friction

- Load Capacity: Heavy-duty runners should handle 5-10kg per runner minimum

When buying from China or other wholesale suppliers, request detailed specifications on wheel composition. Lower-cost alternatives may use inferior plastics that deteriorate under UV exposure or high-use environments.

Calculating Load-Bearing Requirements

This is non-negotiable for commercial projects. Always calculate total curtain weight and divide by the number of runners you’ll install:

Total Curtain Weight ÷ Number of Runners = Load Per Runner

For a 50kg curtain with 5 runners, each runner must support 10kg. Heavy-duty commercial runners should exceed this requirement by at least 20-30% for safety margins. Never compromise on load capacity—it’s a liability issue.

Types of Aluminum Curtain Runners Available

Standard Manual Runners

Traditional manual runners are the most affordable option and work well for applications with moderate use. They feature simple mechanical operation, minimal maintenance requirements, and cost-effective pricing for large-scale installations. Best for budget-conscious projects, heritage installations, or spaces where manual control is acceptable, such as hotels, offices, and residential buildings.

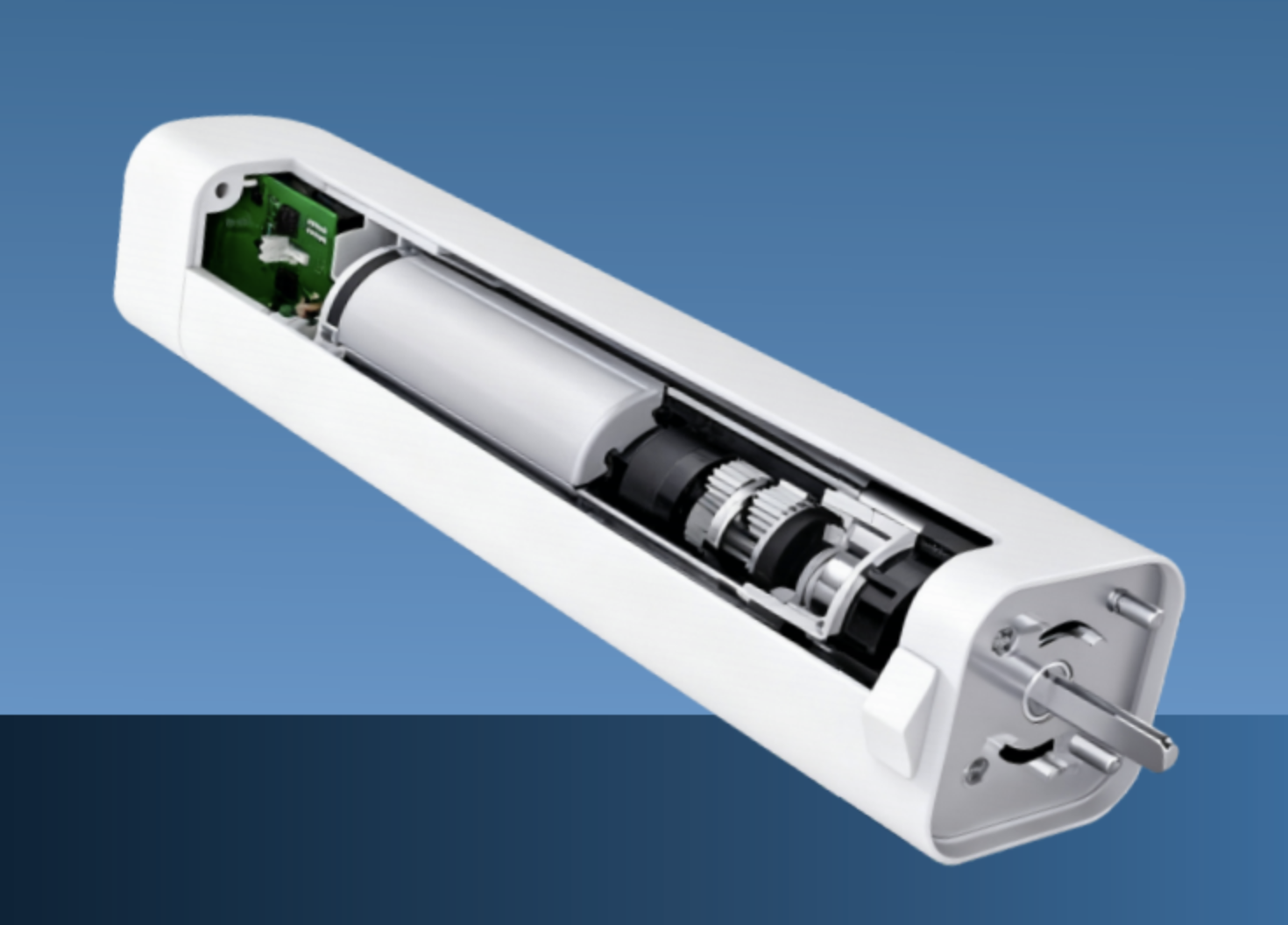

Motorized Heavy-Duty Runners

For premium applications requiring automation, motorized curtain runners offer remote control operation (wireless or hardwired), smart home integration capabilities, quiet and smooth automated opening and closing, and schedule programming for energy efficiency. While they have a higher initial cost, they provide an enhanced guest or employee experience. Ideal for luxury hotels, high-end office buildings, hospitals, and facilities prioritizing automation and convenience.

Corrosion-Resistant Options for Challenging Environments

For coastal areas, industrial zones, and high-humidity spaces, corrosion-resistant runners feature stainless steel or powder-coated finishes, enhanced durability against salt spray and moisture, and significantly extended lifespan. Though the cost is higher, these are essential for coastal properties, industrial facilities, kitchens, and bathrooms where corrosion is a concern.

Wholesale Sourcing Strategies: China vs. Local Suppliers

Advantages of Buying from Chinese Manufacturers

Chinese wholesale suppliers offer significantly lower unit costs (30-50% savings on bulk orders), established supply chains for consistent quality, ability to customize specifications for large projects, multiple finish options and designs, and dedicated wholesale pricing for B2B buyers. However, considerations include longer lead times (4-8 weeks typically), quality variation by manufacturer requiring due diligence, international shipping and import documentation, communication barriers requiring clear specifications, and MOQ (minimum order quantities) typically ranging from 500-1000 units.

Quality assurance tips: Request samples, verify certifications, ask for references from other B2B buyers, and specify exact aluminum composition (6063-T5 is standard for commercial tracks).

Working with Local Wholesale Suppliers

Local suppliers provide faster delivery times, direct quality inspection before purchase, no import complications, easier returns or warranty claims, and personal relationships with sales teams. The trade-off is generally 20-40% higher pricing, limited stock of specialty finishes, fewer customization options, and potentially higher minimum orders.

Best approach: For large projects, negotiate with local suppliers using China wholesale pricing as a benchmark. Many are willing to match pricing for significant orders.

Selecting the Right Finish and Color Options

Aluminum curtain runners and tracks come in various finishes that affect both aesthetics and performance:

- White (Most Common): Clean, modern appearance; works with most interior designs; good for residential and office settings

- Silver/Aluminum: Professional, neutral tone; excellent for contemporary designs; slightly more visible than white

- Black/Dark Finishes: Modern, premium appearance; ideal for luxury hotels and upscale offices; hides dust better

- Anodized Colors: Custom colors available; superior durability; perfect for branded environments

- Powder-Coated Options: Maximum durability; full color range available; best for challenging environments

For commercial projects, stick with standard finishes (white, silver, black) unless you have specific design requirements. Custom colors increase lead times and costs significantly.

Installation and Maintenance Considerations

Mounting Systems and Structural Requirements

The best curtain runners are worthless if installation is problematic. Consider these factors:

Ceiling-mounted systems are most common for commercial applications but require structural assessment. Wall-mounted systems serve as alternatives for lower windows and require specialized brackets. Ensure bracket spacing follows standard intervals of 60mm for optimal weight distribution, and verify bracket load ratings can handle total system weight plus 20% safety margin.

Designing for Long-Term Maintenance Access

Choose runner designs that allow easy maintenance and future replacement:

- Simple removal without permanent fixtures

- Accessible glider replacement without full track removal

- Clear installation instructions in multiple languages (if international project)

Integration with Existing Infrastructure

If upgrading existing installations, verify runner compatibility with existing tracks, consider whether existing mounting points can support new runners, and plan for interim window treatments during installation.

Premium Features for High-Traffic Commercial Environments

Hotels, hospitals, and public buildings experience millions of opening cycles over decades. Certain applications demand maximum durability with these premium features:

- Reinforced Carriages: Thicker plastic or composite materials resist cracking

- Sealed Bearing Systems: Prevent dust and debris from degrading wheel performance

- Multiple Wheel Configurations: Dual or triple wheels distribute weight and extend runner life

- Nylon vs. Plastic Wheels: Nylon typically outlasts standard plastic by 2-3x

- Smooth Gliding Mechanism: Quality runners should glide with minimal friction, even after years of use

Industry Standards and Testing Requirements

When specifying runners for commercial use, reference these standards:

- DIN specifications: German industrial standards for precision components

- Load testing: Manufacturers should provide cycle testing data (typically 100,000+ cycles)

- Weather resistance: UV and humidity testing for varied climate environments

- Warranty: Premium heavy-duty runners often include 3-5 year warranties

Understanding Curtain Runner Pricing and Value

Pricing varies significantly based on specifications, but understanding the cost structure helps you negotiate effectively.

Typical B2B Wholesale Pricing (per runner)

- Standard Manual Runners: $0.80-$2.00 USD per unit (bulk)

- Premium Heavy-Duty: $1.50-$3.50 USD per unit

- Motorized Runners: $15-$35 USD per unit

- Specialized/Custom: $3-$8+ USD per unit

Cost Optimization Strategies

Order in bulk (1000+ units typically unlock best pricing), standardize specifications to avoid custom options unless essential, order during off-peak seasons when summer slump typically offers better terms, negotiate payment terms for volume discounts or early payment incentives, and consider total cost of ownership since cheaper runners that fail early cost more overall.

Example scenario: A 100-room hotel project requires approximately 2000 runners. Choosing the lowest-cost option saves $2000 but risks failure on 10-20% of units. Spending $1 more per unit ($2000 additional) ensures reliability and eliminates future maintenance costs.

Red Flags When Evaluating Suppliers

Avoid suppliers or products with these warning signs:

- No Specifications Provided: Legitimate manufacturers always provide detailed specs

- Unusually Low Pricing: If it’s 50% below market rates, quality is likely compromised

- No Sample Option: Reputable suppliers offer samples for inspection

- Poor Communication: Difficulty reaching technical support is a major red flag

- No References or Case Studies: Established B2B suppliers can provide project examples

- Inconsistent Quality in Samples: Batch variation indicates poor quality control

- No Warranty or Guarantees: Quality products include warranties; cheap ones don’t

Best Practices for Bulk Ordering Success

Pre-Order Due Diligence

Request and inspect physical samples from multiple suppliers, ask for load testing certificates and performance data, verify aluminum composition (6063-T5 standard), request references from similar projects, confirm lead times, shipping methods and costs, and clarify warranty, return policies, and defect procedures.

During Order Execution

Specify exact quantities, colors, and finishes clearly in writing, include detailed technical drawings if customization is needed, confirm delivery date and shipping terms in contract, request inspection before shipment for quality control, and consider insurance for high-value shipments from overseas.

Post-Delivery Quality Control

Inspect 10-20% of shipment upon arrival for quality, test installation on sample area before full deployment, document any defects immediately with photos, maintain installer training on proper installation techniques, and keep documentation for warranty claims.

Emerging Technologies in Curtain Runner Systems

The curtain track industry continues evolving with innovations including smart integration with IoT-enabled runners that monitor usage and report maintenance needs, eco-friendly materials with recyclable and sustainable component options, enhanced noise reduction for ultra-quiet operation in sensitive environments, self-cleaning mechanisms that resist dust accumulation, and modular systems with components that allow easy customization and upgrades.

Staying informed about emerging technologies helps you future-proof your projects.

Making the Right Choice for Your Commercial Project

Selecting heavy-duty aluminum curtain runners for your commercial project isn’t just about price—it’s about value, reliability, and long-term performance. Whether you’re specifying runners for a luxury hotel, corporate office building, or residential complex, following this comprehensive guide ensures you’ll make informed decisions that serve your project and your clients well.

Key Takeaways

- Verify exact specifications and track compatibility before ordering

- Heavy-duty runners are essential for high-use commercial environments

- Wholesale pricing from established China manufacturers offers excellent value

- Always inspect samples and verify quality before placing large orders

- Balance cost with quality—cheap components often cost more in the long run

- Establish clear communication and documentation with suppliers

By applying these principles, you’ll source reliable curtain runners that deliver smooth, quiet, and durable performance for years to come, while optimizing your project budget and timeline.

Ready to source aluminum curtain runners for your next project? Contact us today for wholesale pricing, samples, and expert consultation on selecting the perfect runner system for your commercial application.