When sourcing curtain runners, most buyers focus on one thing: price. But smart procurement professionals know better. Here are four details that separate quality suppliers from the rest.

1. Material Matters: Stainless Steel vs. Aluminum

Look at the comparison image—can you identify which fastener is stainless steel and which is aluminum? Even side-by-side, most people can’t tell the difference. And if you can’t spot it, you probably won’t ask about it. This is exactly what separates premium products from mediocre ones.

The devil is in the details. Stainless steel fasteners ensure long-term durability and corrosion resistance, while aluminum will degrade over time. Don’t let this detail slip by.

2. Virgin Material vs. Recycled: Know What You’re Getting

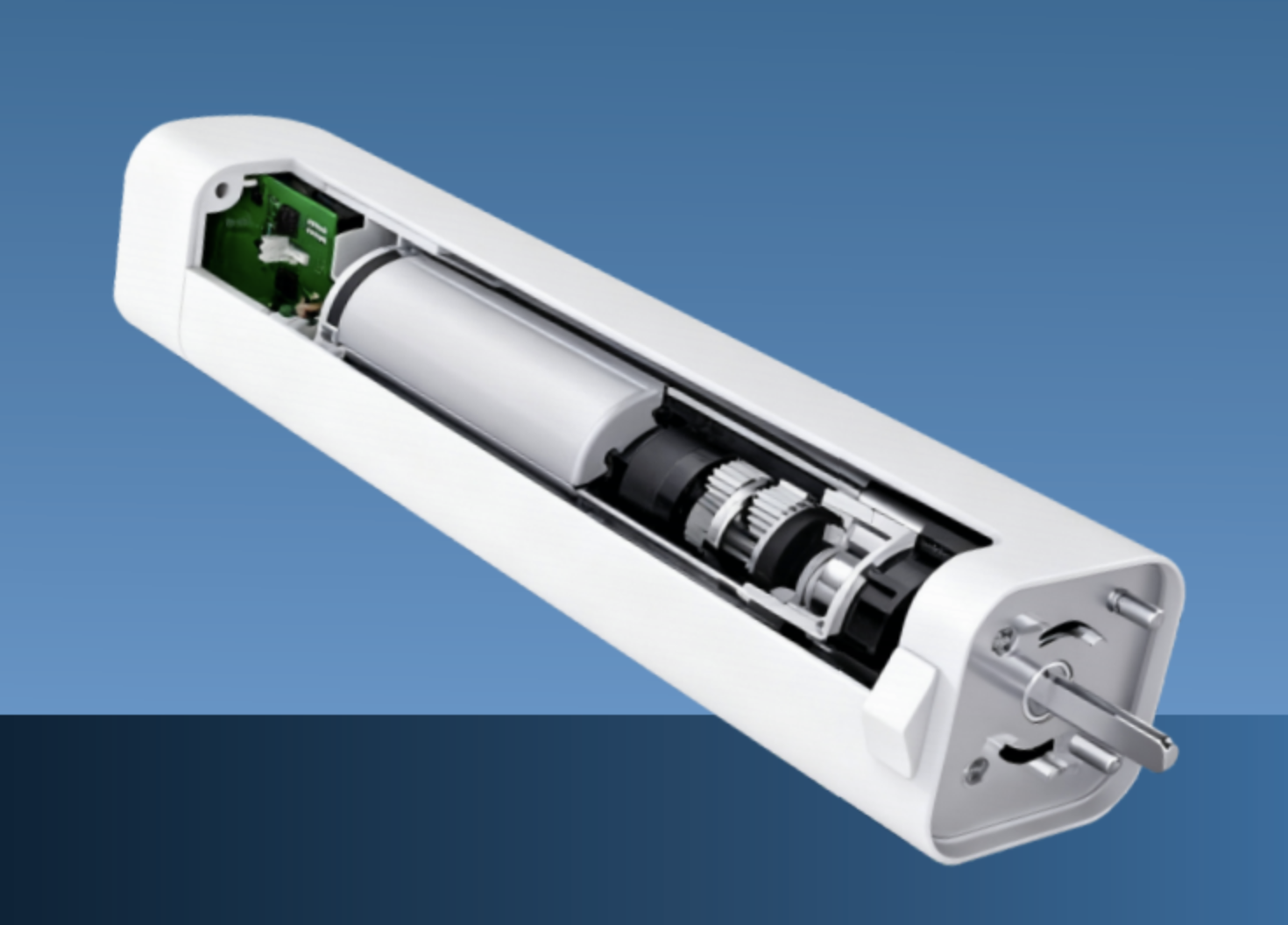

The curtain runner industry primarily uses POM (polyoxymethylene) plastic. This material is prized for its high strength, wear resistance, and low-friction properties—ideal for precision mechanical applications.

Here’s the critical distinction: Only virgin material POM produces runners with smooth surfaces, natural lubrication, and superior wear resistance. Some manufacturers cut corners by using recycled POM—shredded and reprocessed from discarded products. The difference? Almost impossible to detect unless you’re comparing them directly.

Ask your supplier: Is this virgin material or recycled? If they hesitate, that’s your answer.

3. The Right Supplier Asks Questions Too

Any supplier who simply quotes a price without understanding your specific needs should raise a red flag. Why? Because context matters enormously.

We once had a customer complain about noise from a curtain motor system. The motor itself had an excellent track record with thousands of satisfied users. After an hour-long consultation, we identified the real culprit: the customer’s wall material had low density, causing vibration resonance when the curtains moved. The problem wasn’t the motor—it was the installation environment.

The same track and runner combination receives different feedback in different countries. In one market, customers report noise; in another, they report silent operation. Geography, wall type, and installation method all matter. A supplier worth their salt will probe these details before recommending a solution.

4. Your Current Runner Might Be Obsolete

The market evolves rapidly. Components you’ve been using for years may no longer represent the best option available. Modern manufacturing has delivered products that match or exceed the quality of “premium” options—often at significantly lower costs.

Our factory, for example, has developed two patent-pending runner designs that outperform our best-selling models while maintaining lower price points. But here’s the catch: we only recommend these to established customers who’ve built trust with us. Once they switch, they never look back.

Don’t assume your current sourcing is optimal. Ask your supplier what innovations they’ve developed recently. If they can’t articulate meaningful improvements, it might be time to explore alternatives.

The Bottom Line

Quality sourcing is about more than price negotiations. It’s about asking the right questions, understanding material specifications, considering your unique application, and staying informed about market innovations. The suppliers who invest time in understanding your needs—rather than just filling orders—are the ones who’ll ultimately save you money and headaches.