This afternoon, I was sitting in my office having tea and chatting with a client when Zhang, the manager responsible for component molds at the factory, arrived. He brought the new components over for my inspection. After checking the appearance, I felt quite satisfied. After all, our mold production uses virgin POM material throughout, and once molded, both the color appearance and the glossy finish look excellent. This particular S-fold curtain runner is custom-designed—meaning there is no matching off-the-shelf runner available on the market, so it requires custom mold tooling.

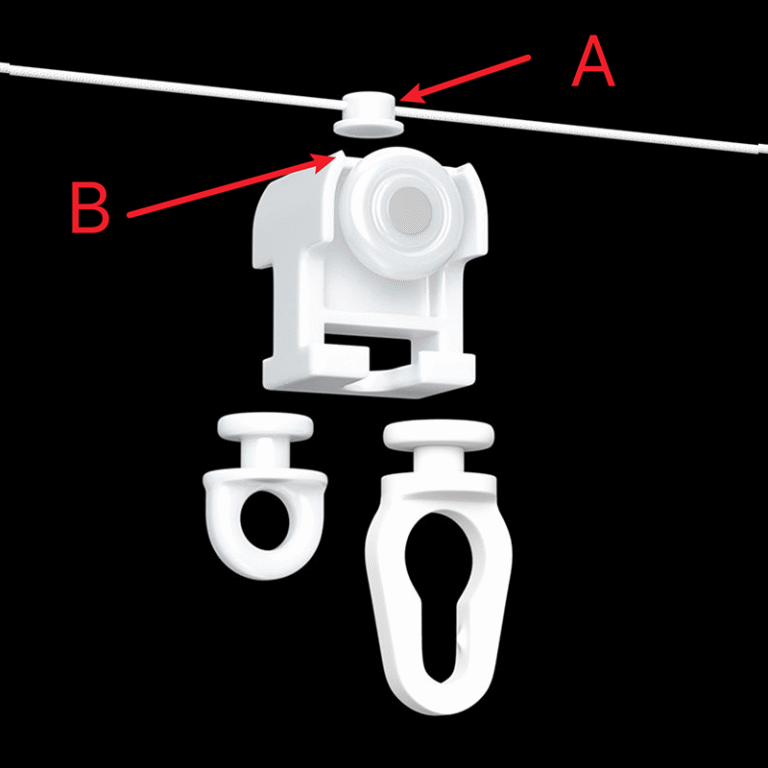

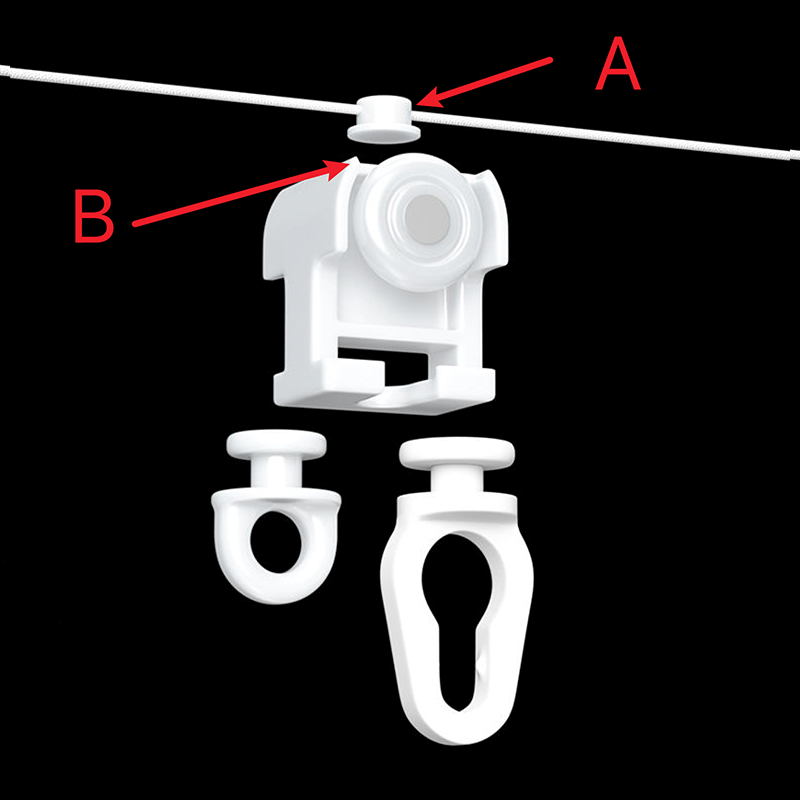

I then took the ball bearing string (shown at position A in the diagram) and used a tool to press it firmly into the groove of this runner (shown at position B in the diagram). Then I pulled it outward with force to check how securely the ball bearing string and the runner fit together. In reality, this level of tightness would already be sufficient for hanging the client’s curtains without issues. After testing three sample components, I noticed that after the ball bearing on the string was pressed into the groove, there were still some gaps. With considerable force, it could still be pulled out.

I understand that this client’s final curtains will be quite heavy—not ordinary residential use. So I explained to Zhang, the manager of the runner component mold, that we need to modify the current mold dimensions. My requirement is that the ball bearing on the string be completely secured in the groove with no movable gaps at all—it should be completely impossible to pull out. I also told him that after making these modifications, we must conduct additional testing, and only when the results meet my specifications can production begin.

Why do I insist on redesigning the mold when it already meets market standards? Although our factory is small, our standards are not compromised. We manufacture all components based on a ten-year service lifespan. The S-fold curtain runner component may be small, but it directly affects how smoothly curtains open and close, and determines their service life. It is precisely through this professional attention to detail that our small factory continues to receive steady orders.

Click here for product details:S-fold-curtain-runners